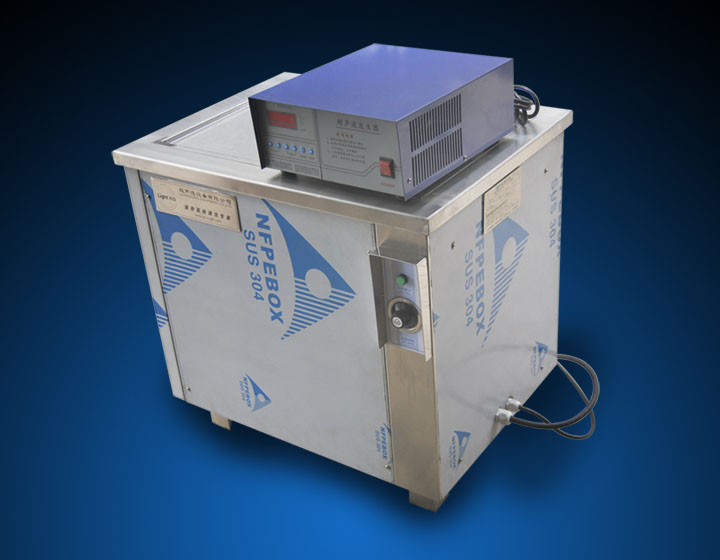

Model: DYS-1024

Ultrasonic frequency: 40KHZ, 28KHZ

Ultrasonic power: 1200W

Adjustable time: 0-30min

Power supply voltage: AC220V±10% 50Hz

Electric heating power: 3KW

Adjustable temperature: normal temperature-110℃

Inner groove size (mm) length (L) × width (W) × height (H): 600 × 400 × 400

Dimensions (mm) Length (L) × Width (W) × Height (H): 720 × 540 × 695

The pre-treatment process of product spraying is very important. The general traditional process uses acid to process the workpiece, which causes heavy environmental pollution and poor working environment. At the same time, the biggest disadvantage is that the residual acid after complex cleaning of the parts is difficult to pick up and remove rust. Rinse. After the workpiece is sprayed, the time is not long, and the rust phenomenon occurs along the crack, which damages the surface of the coating and seriously affects the appearance and internal quality of the product. Ultrasonic cleaning technology is applied to the pre-coating treatment, not only can quickly peel off the dirt on the surface of the object and the gap, but also the coating layer of the painted part is firm and will not return to rust.

Using the cavitation effect of ultrasonic waves in the liquid, the oil stains on the surface of the workpiece can be washed away. With the appropriate cleaning agent, the surface of the workpiece can be quickly treated with high cleanliness. Electroplating process requires high surface cleanliness, and ultrasonic cleaning technology is an ideal technology to meet this requirement. Using ultrasonic cleaning technology, it can replace the solvent to clean the oil; it can replace the electric oil removal; it can replace the strong acid etching to remove the rust and scale on the surface of carbon steel and low alloy steel.

Brief introduction of ultrasonic cleaning process for several common workpiece surface conditions:

1. Cleaning of polishing paste on polishing surface

In general, the polishing paste is often blended with paraffin wax. The paraffin wax has a large molecular weight, a high melting point, and a solid state at room temperature. It is a difficult-to-clean substance. The traditional method is to use organic solvents to clean or high-temperature alkaline water to wash. Ultrasonic cleaning can use water-based cleaning agent, under moderate temperature conditions, the surface of the workpiece is thoroughly cleaned within a few minutes, the common process is: ① soak → ② ultrasonic cleaning → ③ clean water (clean water) rinse.

2. Cold rolled steel plate with oil and a small amount of rust on the surface

The surface of the cold-rolled steel plate generally has oil, dirt or a small amount of rust. It is easier to clean it. However, after cleaning by a general method, a very thin layer of floating ash remains on the surface of the workpiece, which affects the quality of subsequent processing. Sometimes it is necessary to use strong acid Soak the method to remove this layer of floating ash. The use of ultrasonic cleaning and the addition of appropriate cleaning fluid can easily and quickly achieve a thorough cleaning of the surface of the workpiece, and make the surface of the workpiece highly active, and sometimes even avoid the acid leaching activation process before electroplating.

3. Workpieces with oxide scale and yellow rust on the surface The traditional method is to use hydrochloric acid or sulfuric acid to soak and clean. If the ultrasonic comprehensive treatment technology is adopted, the oil and rust on the surface of the workpiece can be quickly removed in a few minutes, and the hydrogen embrittlement problem caused by strong acid cleaning can be avoided.

Main performance and characteristics:

1. The overall stainless steel structure of the machine is beautiful and durable, simple and convenient to operate, and can be used after plugging in the power supply.

2. The machine adopts 28KHZ and 40KHz ultrasonic waves to effectively reduce noise and improve cleaning efficiency.

3. The cleaning time can be adjusted freely within 60 minutes (in seconds) to reach the cleaning standard.

4. The machine is equipped with an independent drainage ball valve for manual drainage.

5. Electric box features: The new dual-frequency circuit has the following functions: infinitely adjustable power, dual-frequency sweep frequency tracking, digital display frequency display, digital display power display, digital display current display and digital display timing cleaning. (According to the cleaning of different workpieces, to achieve a standard and uniform cleaning effect)

6. Heating function: equipped with a constant temperature mechanical thermostat, which automatically stops heating after reaching the design temperature, and automatically heats when it is lower than the set temperature (heating power: 1-3KW optional)